Wall grinding is a very important link in wall finishing, which is an important way to improve the flatness, details and final effects of wall surface.

Whether by day or night, when grinding the wall surface, you must be armed with a 200 - watt light bulb at least in order to observe the wall roughness.

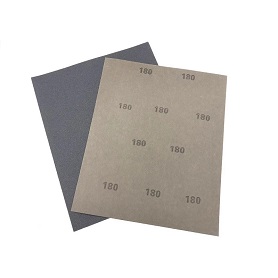

At the same time, on the selection for sandpaper, generally speaking, people will begin with fine sandpaper, not as thick as possible, or as thin as possible. If it doesn’t work, people will change it into coarse sandpaper, but in the end, they will use fine sandpaper to polish it again, to ensure no scratches on the wall surface.

Good decoration workers will recommend using water resistant putty in order to improve the wall surface’s service life of owners’ house, even if it will be polished a little bit difficult.

In addition, the best water resistant putty needs to be used as soon as possible, better within three days, because it has low intensity at this time, and the surface structure is not yet solid.

To achieve better effect, people can use first 120 sandpaper for grinding in the first pass, and fine sandpaper more than 360 mesh for the second time. The bonding strength of putty directly determines the future of life and resistance to water. In allowable conditions, using higher bonding strength water resistant putty has higher cost performance for a long time.

Nanchang Dove Industrial Materials Co., Ltd. and CIPIE(Henan)Import and Export Trade Co.,LTD. as two great abrasives suppliers, can supply great quality sandpapers and professional services. View more products or make contacts, please click the links above.

Related News

- Sharpness Compactgrain Abrasive Belts Introduction2020-04-13

- The sharpness brand cutting disc series of Yuli Group passed EU MPA certification again2020-01-16

- Rhombus shaped Products Introduction2020-01-02

- Yuli Group passed the certification of FSC again2019-12-24

- Yuli Group attended The 126th Canton Fair2019-10-17