Compactgrain abrasive belts is a new type of coated abrasive products developed by Yuli group, which has the following advantages:

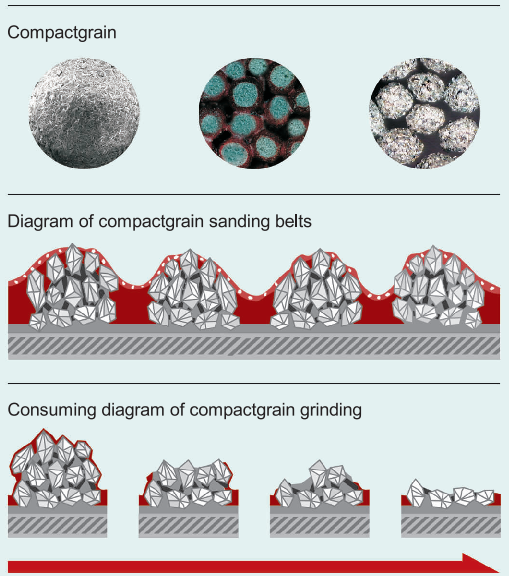

1.Long grinding life,compactgrain abrasive belt is different from the ordinary plane coated abrasive belt.The compactgrain is made of many small abrasive agglmerates, so there are more abrasives per unit area,and it has long service life.The life of compactgrain abrasive belt is 3-5 times longer than convetional abrasive belts.so it can reduce the number of times of replacing the belts and improve the processing efficiency.

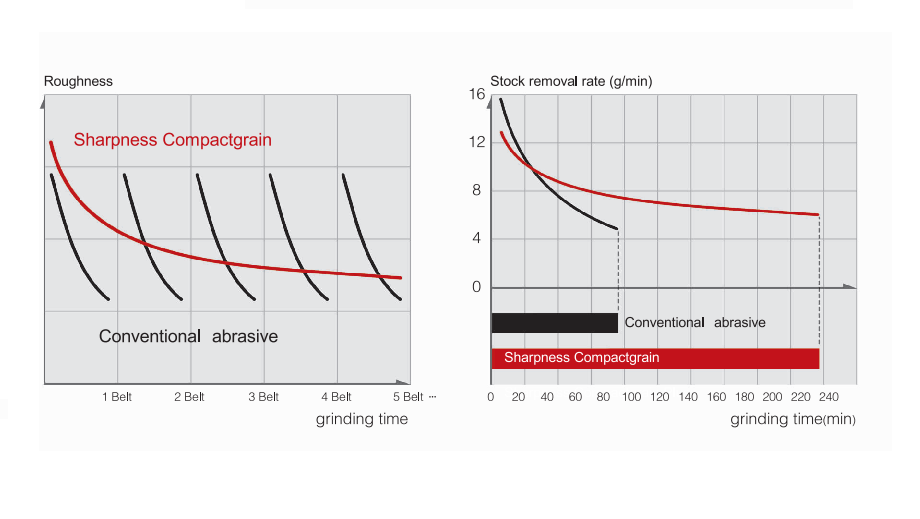

2.optimum self-sharpening effect, When the compactgrain abrasive belts is worn, the accumulated structure is worn, and the abrasive inside is continuously exposed. These new abrasives have sharp corners and maintain the sharpness of the entire grinding process. When the traditional abrasive belt is worn, the abrasive is continuously blunt, forming blunt facets, and the sharpness gradually decreases.

3.constant roughness and stable gloss value. The surface roughness of compactgrain can be available consistently while grinding.Meanwhile, the surface roughness of conventional abrasive products varies a lot.

4.Low grinding heat.The surface segments keep falling off during grinding process and taking excessive grinding heat away from the belts.

At present, Yuli's compactgrain abrasive belt products have been upgraded and improved, and have developed soft cloth, hard cloth, ultra-wide series, with grit from P80-P1000, which can fully meet the market for metal wire drawing, plate polishing, electronic product surface Deal with other needs. It has successfully entered the domestic military industry, replacing imported products, and polishing titanium alloy plates for aircraft and submarines.

Related News

- Sharpness Compactgrain Abrasive Belts Introduction2020-04-13

- The sharpness brand cutting disc series of Yuli Group passed EU MPA certification again2020-01-16

- Rhombus shaped Products Introduction2020-01-02

- Yuli Group passed the certification of FSC again2019-12-24

- Yuli Group attended The 126th Canton Fair2019-10-17